Termotron Factory

Our products are your safety!

Many years of experience

JSC Termotron-Zavod is a full—cycle Russian machine-building enterprise. For over 30 years the plant has been producing a wide range of hi-tech, advanced, innovative products designed for traffic safety on railways, metro lines and urban rail transport in Russia, CIS and non-CIS countries.

Full production cycle

Our own design-engineering department, the unique foundry production, extensive processing capabilities, the innovative coating workshop, modern assembling and welding areas, the multistage quality control system, the test laboratory and the responsibility of every worker for the result achieved ensure high quality of our products.

- quality

- safety

- responsibility

- initiative

- quality

- safety

- responsibility

- initiative

- competence

- reliability

- functionality

- competence

- reliability

- functionality

- competence

- reliability

- functionality

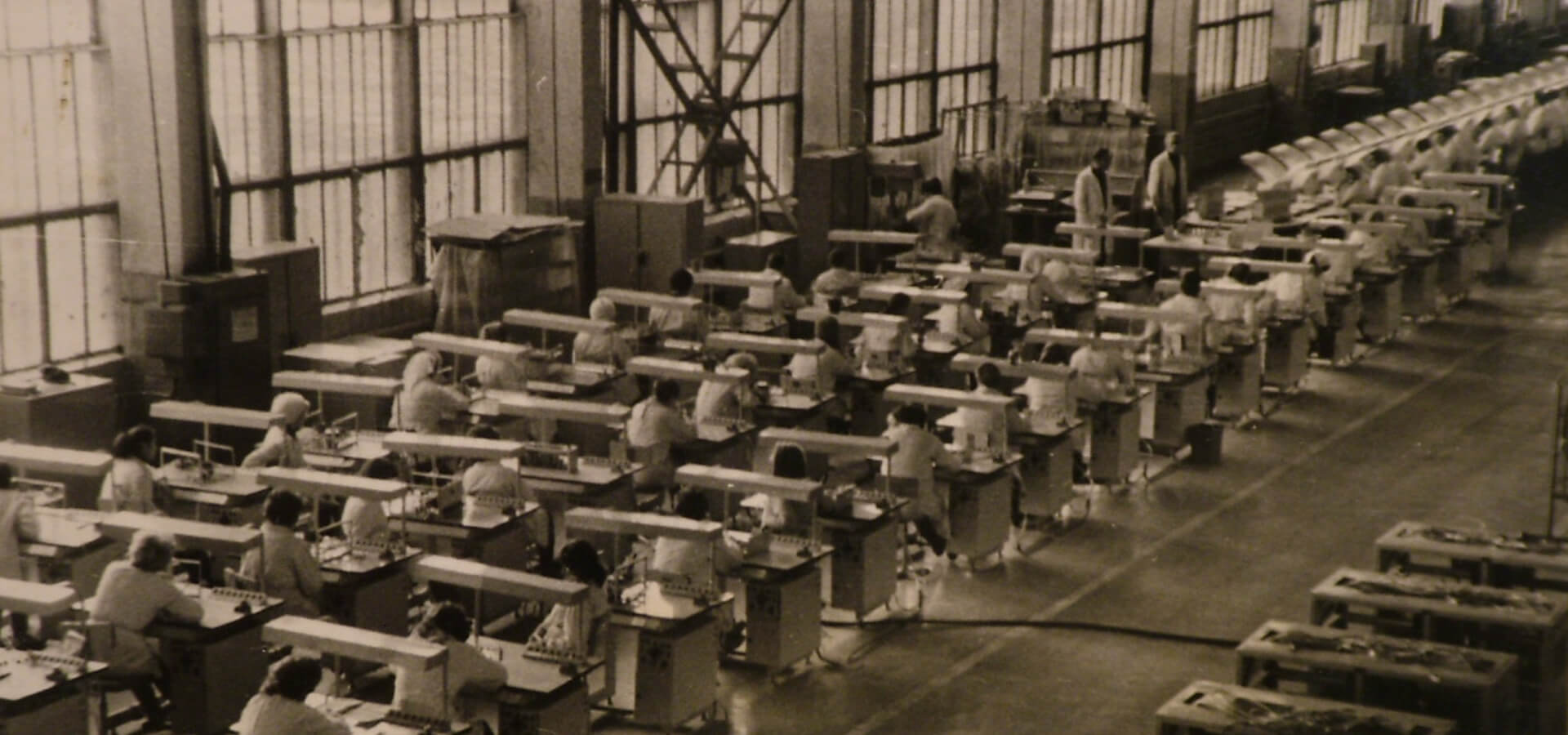

History

A combination of tradition and innovation

The company observes the traditions which in combination with many years' experience and wide process capabilities enable to produce reliable serial equipment for railways and underground railway systems and create the unique process equipment in compliance with individual technical specifications of customers.

Work on the result

Technological equipment with the brand Termotron is characterized by high reliability, performance, energy saving, control automation, accuracy of maintaining operating parameters, ease of operation, quality of manufacture, design and service.